I've been busy on non-ham activities the last few weeks so I haven't progressed many projects. I'm re-organising the workshop and trying to throw out some equipment surplus to requirements. My wife calls it junk!

I had a few SCSI tape drives lying around and as I opened one up to recover the controller board it occurred to me I could make a tank agitator for etching. In the past I had used an aquarium bubbler with an air stone. I stopped using this because it generated a plume of etchant that stained nearby objects. I moved on to putting the pcb in a zip lock back and manually rocking it while it sat in a dish.

This works well but if I could automate the rocking and heat it at the same time things would be better. I'm blessed with a working stove and hot plates in the workshop, but don't tell the wife or I might be expected to move into the workshop for good.

So there when I opened the SCSI drive was a great big cog used to load the tape. It took all of 5 minutes to work out there was a lug underneath the cog I had to chop off so it could rotate continuously and wire up a plug pack to the motor. A few more minutes to work out how to attach the rotating cog to the etchant bath and I was done. I used a bolt onto a pop stick, or small piece of wood found in frozen ice sweets, and a piece of string from the wood to a peg on the dish.

With the hotplate turned on and the motor running things went smoothly. The only issue is the dish tends to walk around the surface of the hot plate. I'm going to fix that by running the cord over an arm and pulley perhaps 50cm above the etchant tank. That way the lifting on the tank will be vertical instead of including a side to side motion as well.

The current arrangement looks like this before I make the arm and pulley:

A very temporary proof of concept. Which just goes to show that one man's junk can contain his treasure.

Regards

Richard VK6TT

A blog about homebrew projects for Ham Radio. I cover aerials, test equipment, transmitters, both QRP and QRO, receivers and transceivers. The emphasis is on design and building. Generally I have boards and parts available at a modest cost. If you need more details, like a board layout, or any questions please ask. I'm more than happy to help.

Wednesday, 17 May 2017

Friday, 5 May 2017

Heatsink Fan Temperature Switch

As I was pondering the next step with my bag of 2SC5707 transistors the problem of heat-sinking occurred to me. An elegant solution would be to mount the transistors to the PCB but the cooling is awkward. Then I remembered how effective forced air cooling is and remembered I hadn't shared this with readers before.

I put most commercial class VHF FM transceivers way ahead of ham gear when it comes to selectivity and immunity from pagers. The only drawback I have ever noticed was with regard to transmitting duty cycle. Generally, the commercial transceiver was never intended for long overs and the heat-sinking reflects this. Fine for repeater use but if you have a long over on simplex things get hot. Sometimes very hot!

Here is a simple project that really protects that radio. First, the results of before and after measurement of heat-sink temperatures are shown below on a Philips PRM80 transmitting 25 watts into a dummy load:

It is true that many transmissions do not last 3 minutes or longer. However, a high SWR at the radio will increase the heat dissipated by the final transistor. I generally only check my antenna when I suspect it needs to be checked. So I could be transmitting for some time before any problem is detected. And while I have never sat on the microphone I am sure we have all heard someone driving around with the transmitter keyed up for extended periods.

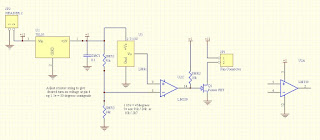

I consider this a worthwhile addition to any PMR type radio. From the circuit below you will see that when the output of the temperature sensor reaches a set point the fan is turned on. Once the temperature falls the fan turns off.

I made mine on a small 0.8mm thick piece of PCB so that the surface mount LM61 could be mounted in a slot in the board to make contact with the heat-sink when the pcb was bolted to the heat-sink.

I'm going to use the same circuit on a forthcoming experimental HF amplifier using all of my remaining 2SC5707's. One last hurrah for them or a successful 15 watt linear amplifier for the lower HF bands.

Regards

Richard VK6TT

I put most commercial class VHF FM transceivers way ahead of ham gear when it comes to selectivity and immunity from pagers. The only drawback I have ever noticed was with regard to transmitting duty cycle. Generally, the commercial transceiver was never intended for long overs and the heat-sinking reflects this. Fine for repeater use but if you have a long over on simplex things get hot. Sometimes very hot!

Here is a simple project that really protects that radio. First, the results of before and after measurement of heat-sink temperatures are shown below on a Philips PRM80 transmitting 25 watts into a dummy load:

It is true that many transmissions do not last 3 minutes or longer. However, a high SWR at the radio will increase the heat dissipated by the final transistor. I generally only check my antenna when I suspect it needs to be checked. So I could be transmitting for some time before any problem is detected. And while I have never sat on the microphone I am sure we have all heard someone driving around with the transmitter keyed up for extended periods.

I consider this a worthwhile addition to any PMR type radio. From the circuit below you will see that when the output of the temperature sensor reaches a set point the fan is turned on. Once the temperature falls the fan turns off.

I made mine on a small 0.8mm thick piece of PCB so that the surface mount LM61 could be mounted in a slot in the board to make contact with the heat-sink when the pcb was bolted to the heat-sink.

I'm going to use the same circuit on a forthcoming experimental HF amplifier using all of my remaining 2SC5707's. One last hurrah for them or a successful 15 watt linear amplifier for the lower HF bands.

Regards

Richard VK6TT

Subscribe to:

Comments (Atom)