First please excuse me for a heading that sounds like click-bait. I'm just very excited at the results to data and wanted to share progress with you.

It is important to remember that during the entire life of the battery there is no change in the rate or the intensity of the flashing. No feeble blinking allowed in my projects!

The Joule Thief was a wonderful circuit for getting light loads to operate from batteries that were essentially flat. I built many of them and was amazed at the results. However, I stumbled across boost convertor IC's which cost cents and delivered even better results for no engineering effort on my part.

Recently I tried a variety of circuits for flashing a LED. My need was to be able to see if the gate to our property had been closed at night without walking all the way there. I didn't want to turn on the driveway lights because one of the benefits of going outside with the dog before bed is the night sky. The driveway lights detract from that. And where's the fun in painting a black gate white!

Testing showed that using a micro to flash a LED was way more efficient that discrete versions of LED flasher circuits. Building on this example I made some code changes to enable pull-ups on unused inputs and adjusted the timing to suit my needs.

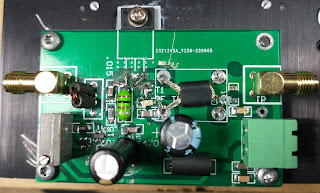

Instead of powering this from a 3V battery I used a AA battery and a boost convertor. It was obvious from the start of testing that this was going to be a step change in how long a AA battery could be made to flash a LED. Several years looked possible so I used an AG3 battery to test the concept.

The quoted capacity of an AG3 cell varies from 25 to 35 mAh. Based on earlier measurements I expected an average current draw of roughly 100uA, say 250 hours or 10 days. I used a brand new cell that was several years old from an unknown Chinese battery manufacturer. Given my contempt for most things purchased via AliExpress I would have been satisfied with 5 days given my expectation of 10 days.

After 15 days the battery voltage was still 1.205 volts. It appears from extrapolating the measurements that the AG3 will will last around 25 days.

I have a Joule Smasher Led Flasher running on a brand new AA battery. That battery still reads 1.555 volts after 15 days. It's a wild guess but if the 25-35mAh capacity of the AG3 is comparable to the 3000mAh of an alkaline AA then the Joule Smasher should flash the LED for 6 to 8 years. That exceeds my wildest expectations and is far longer than I expect to be living at this property.

There is still room for improvement. I'm boosting the battery to 3.3V because at the time of building that was the part I had to hand. So I'm wasting a significant amount of energy in the current limiting resistor in series with the led. That might represent an increase of 20% in battery life.

Sometime next year I'll build a few more of these to confirm results and check the benefit of boosting to 3V or 2.7V.